The European mining industry is increasingly looking for solutions to redesign traditional mining processes through the adoption of pioneering innovations, accompanied by the extensive use of data analytics and new types of technology use, in particular the Industrial Internet of Things (IIoT). The EU-funded illuMINEation project will create a multi-level distributed IIoT platform, which will be developed by a consortium created together with PSNC.

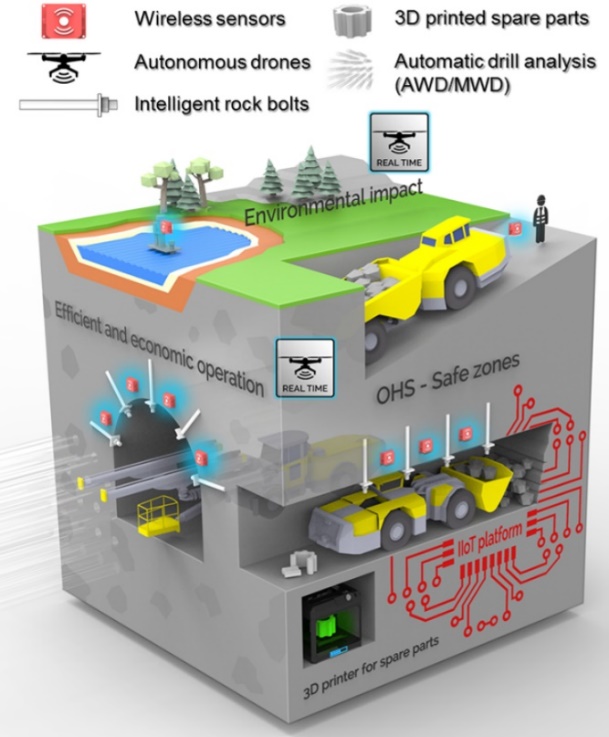

The project started in September 2020. Its purpose is to highlight the significant aspects of digitization in mining operations in order to achieve the highest possible level of safety, environmental protection and to improve economic performance. As part of the project, a multi-level distributed IIoT platform will be created, including edge and cloud computing and distributed data management based on large sensor networks with the possibility of conducting wireless data acquisition. Advanced user interfaces, dashboards and AR / VR applications will be designed, allowing for modern information flow and management. A rigorous approach to cybersecurity will ensure adequate protection of all processed data.

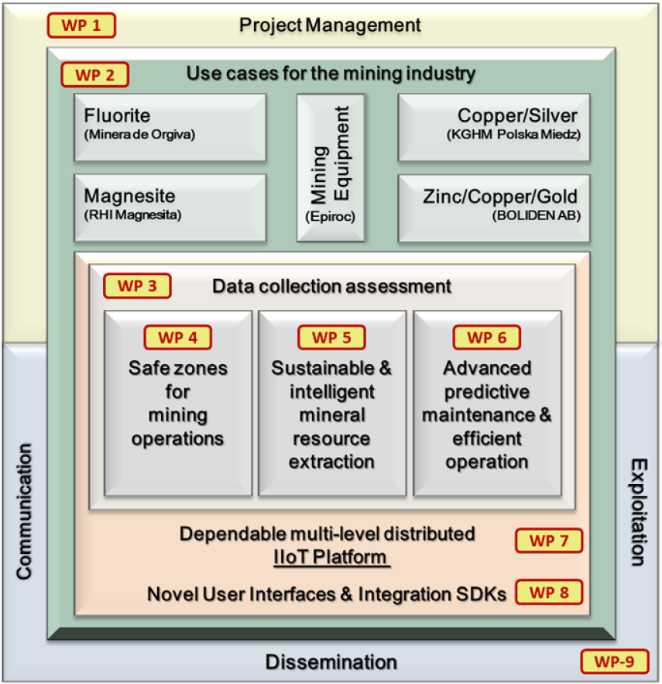

The design of the illuMINEation platform was based on specific use cases and challenges faced by the consortium partners (mining companies and equipment manufacturers) and on the challenges faced by technology companies in their operations. The assumed case-by-case approach guarantees the product development required by industry and meeting urgent needs to ensure safe, environmentally friendly, efficient and sustainable production of raw materials.

Comprehensive digitization of important mining aspects will be carried out, such as mine deposits, rock mass stability, equipment condition monitoring, mining personnel safety, as well as the working environment and the mine. The IlluMINEation project addresses all three key factors that influence the sustainability and profitability of mining operations:

• health and safety performance (including health and safety aspects of a nearby community)

• impact on the environment

• efficient extraction of raw materials and economic operation

Large sensor networks installed throughout the mine will allow continuous data collection and model building through incremental learning methods based on artificial intelligence, probabilistic methods, statistical and dynamic optimization methods.

One of the main goals of the IlluMINEation project is to improve the efficiency of mining operations and to improve the health and safety of personnel. The fulfillment of these assumptions may also bring wide benefits, also social, for the mining industry: social acceptance of mining operations or making mining companies more attractive as potential employers. The project will demonstrate the interaction of many different sensor types and heterogeneous data streams to optimize decision making. In addition, project outcomes will lay the foundations for future digital products including both high-end hardware and software, seamlessly integrated via an open, standards-based architecture, offering enormous potential for exploiting the technologies for the use of these technologies in non-EU markets.

The IlluMINEation project is expected to become the start of other initiatives and a role model for a number of detailed follow-up pilots to digitize European mining operations to an internationally competitive level.

The areas supported by the PSNC team are primarily the process of designing a complete IIoT distributed data processing platform at every level (Edge, Fog and Cloud). PSNC will also provide the computing and database infrastructure required by the IlluMINEation platform in accordance with the assumptions agreed with the results of the design work. Additionally, various packages will be supported with our knowledge and experience in the field of Big Data, AI and data analytics solutions from the perspective of the HPC unit.

Together, the project partners form a high-quality multidisciplinary consortium characterized by a well-balanced gathering of the world’s leading industrial and academic players from many fields, both technical and application, such as: geology, mining, environmental sciences, process modeling and simulation, sensor developers, IT network companies , IIoT specialists, cybersecurity experts, etc. Most importantly, four European mining companies (Mineral de Orgiva, Spain; Boliden, Sweden; RHI Magnesita, Austria and KGHM Polska Miedź, Poland) and one of the world’s leading mining equipment companies ( EPI-Sweden) are part of the project team, together forming a group of use case partners.

In summary, the illuMINEation consortium has the experience, knowledge, know-how and state-of-the-art facilities needed to fully exploit the potential of digital innovation. The consortium consists of 19 partners from six European countries (Austria, Sweden, Poland, Germany, Spain and Finland) bringing together the expertise of seven universities and research organizations and seven partners from the industrial sector.